Teknologi Disipasi Energi Benturan Superior

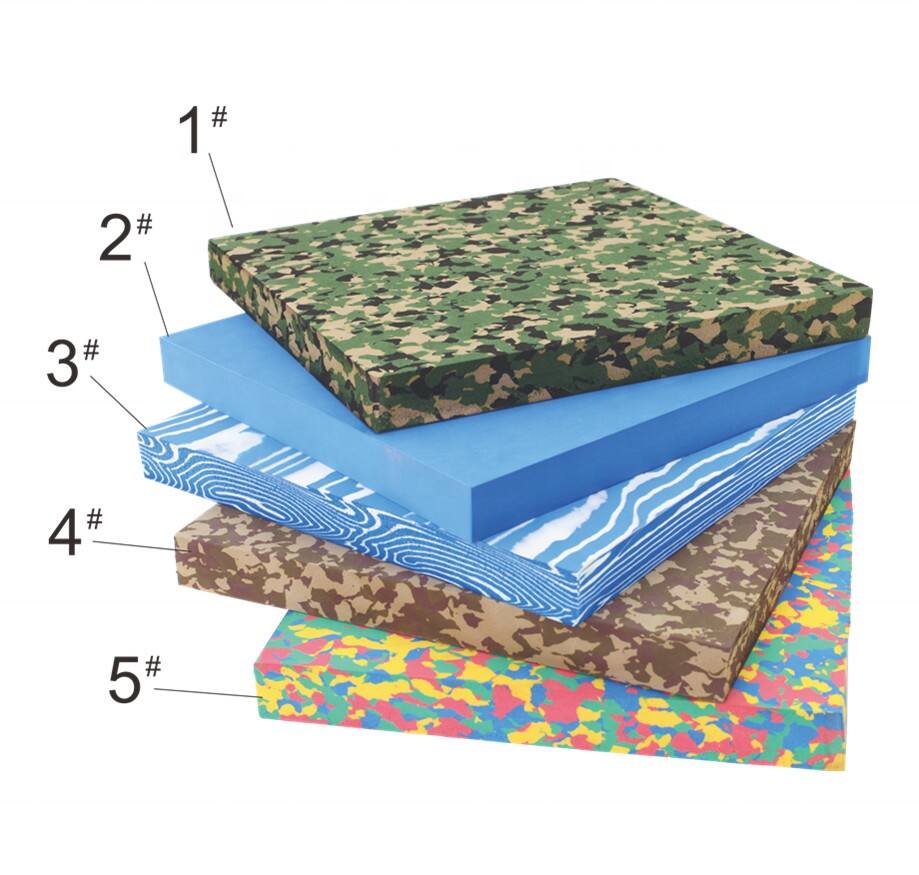

Struktur molekuler canggih dari silikon penyerap kejut menandai terobosan dalam teknologi perlindungan benturan. Pada intinya, material ini menggunakan jaringan kompleks polimer silikon yang saling terhubung, yang dirancang secara khusus untuk menangkap dan menghamburkan energi kinetik dari benturan. Struktur unik ini menciptakan pola deformasi terkendali yang secara efisien menyebarkan gaya benturan ke area yang lebih luas, secara signifikan mengurangi titik tekanan maksimum. Susunan molekuler material ini memungkinkan konversi energi yang cepat, mengubah gaya benturan yang berpotensi merusak menjadi energi panas yang tidak berbahaya dan segera hilang. Proses ini terjadi dalam hitungan milidetik, memberikan perlindungan instan terhadap benturan mendadak. Kemampuan material mempertahankan kinerjanya selama ribuan siklus benturan membuatnya menjadi solusi yang sangat andal untuk kebutuhan perlindungan jangka panjang.