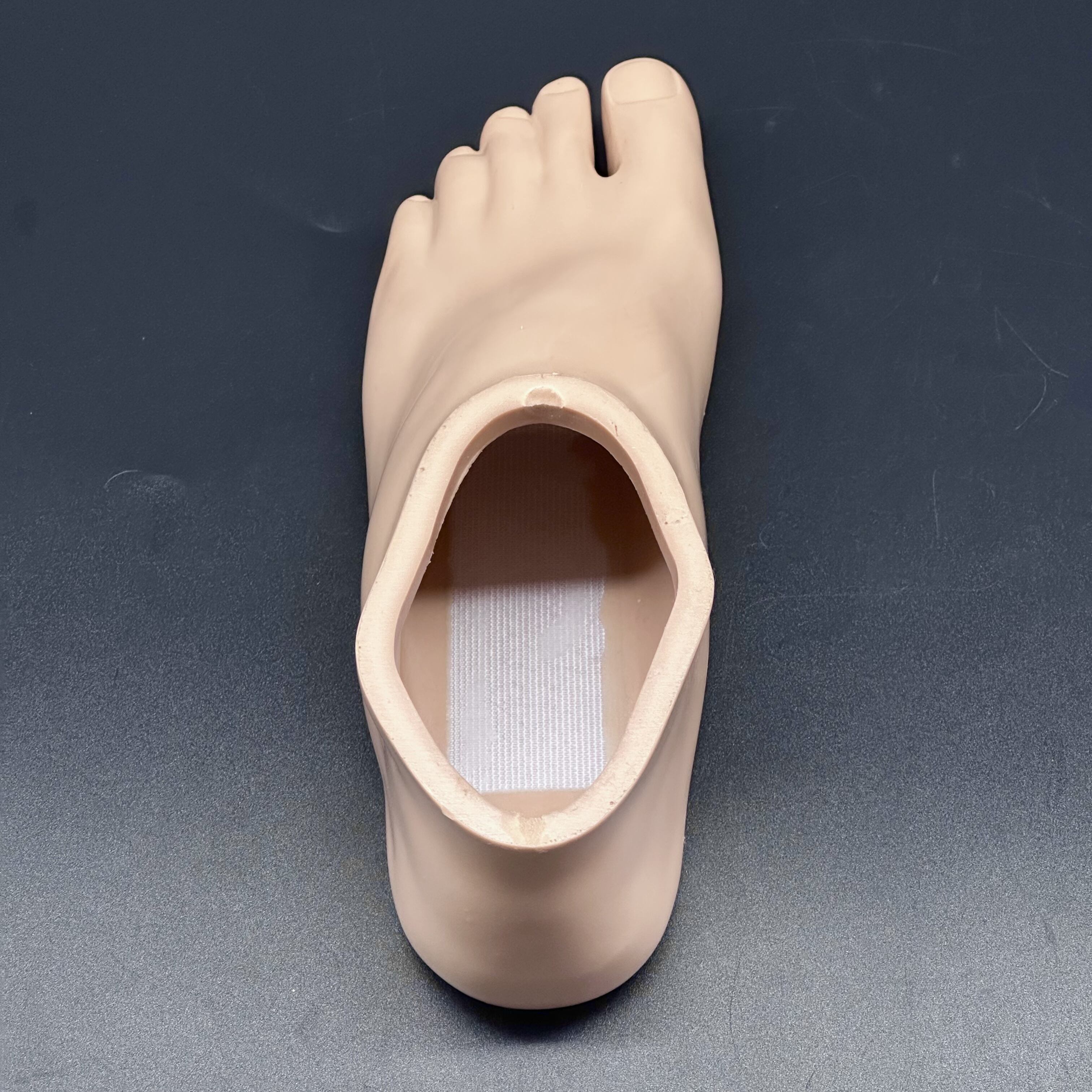

Prosthetic feet made from polyurethane materials have revolutionized the way amputees experience comfort, durability, and natural movement. Unlike traditional materials, a polyurethane foot offers superior protection for sensitive residual limbs while maintaining the flexibility needed for daily activities. This advanced material technology addresses the unique challenges faced by prosthetic users, particularly those with delicate skin conditions or heightened sensitivity around the amputation site.

The development of polyurethane technology in prosthetics represents a significant advancement in patient care and comfort. Medical professionals consistently recommend polyurethane foot solutions for patients who experience irritation, pressure sores, or discomfort with conventional prosthetic materials. The unique properties of polyurethane create an optimal environment for healing and long-term wear, making it an essential consideration for anyone seeking enhanced prosthetic performance.

Understanding Polyurethane Material Properties in Prosthetics

Chemical Composition and Biocompatibility

Polyurethane represents a class of polymers created through the reaction of organic units joined by carbamate links. In prosthetic applications, medical-grade polyurethane undergoes rigorous testing to ensure complete biocompatibility with human tissue. The material's molecular structure allows for exceptional flexibility while maintaining structural integrity under repeated stress cycles.

The biocompatible nature of polyurethane foot components means reduced risk of allergic reactions or skin irritation. Unlike some synthetic materials that can cause contact dermatitis, medical-grade polyurethane has been extensively tested for skin sensitivity. This makes it particularly suitable for users with compromised skin integrity or those prone to allergic reactions.

Durability and Longevity Characteristics

A well-manufactured polyurethane foot demonstrates remarkable resistance to wear, tear, and environmental factors. The material maintains its structural properties across a wide temperature range, ensuring consistent performance in various climatic conditions. This durability translates to longer replacement intervals and reduced maintenance costs for users.

Testing data indicates that polyurethane prosthetic components can withstand millions of loading cycles without significant degradation. This exceptional fatigue resistance makes polyurethane foot options ideal for active individuals who place demanding requirements on their prosthetic devices. The material's ability to return to its original shape after compression ensures consistent comfort and performance over extended periods.

Benefits for Sensitive Skin Conditions

Reduced Friction and Pressure Distribution

Individuals with sensitive skin conditions often struggle with traditional prosthetic materials that create friction hotspots and uneven pressure distribution. A polyurethane foot addresses these concerns through its unique ability to conform to the residual limb's contours while distributing forces evenly across the contact surface. This property significantly reduces the likelihood of developing pressure sores or skin breakdown.

The soft, yielding nature of polyurethane allows the material to deform slightly under load, creating a cushioning effect that protects delicate tissues. This characteristic is particularly beneficial for users with diabetes, peripheral vascular disease, or other conditions that compromise skin integrity and healing capacity.

Moisture Management Properties

Effective moisture management is crucial for maintaining healthy skin conditions under prosthetic devices. Polyurethane foot materials excel in this area through their controlled permeability properties. The material allows for adequate ventilation while preventing excessive moisture accumulation that can lead to bacterial growth and skin maceration.

The antimicrobial properties inherent in certain polyurethane formulations provide additional protection against bacterial and fungal infections. This feature is particularly valuable for users who experience excessive perspiration or live in humid climates where moisture-related skin problems are common.

Residual Limb Protection Mechanisms

Shock Absorption and Energy Return

The viscoelastic properties of polyurethane enable superior shock absorption during heel strike and weight-bearing activities. A polyurethane foot can absorb impact forces that would otherwise be transmitted directly to the residual limb, reducing stress on sensitive tissues and joints. This protection is essential for preventing pain and long-term damage to the amputation site.

Beyond shock absorption, polyurethane materials provide controlled energy return during the push-off phase of walking. This characteristic reduces the metabolic cost of ambulation while providing a more natural gait pattern. The energy storage and release properties of polyurethane contribute to reduced fatigue and improved walking efficiency.

Adaptive Fit and Comfort Features

One of the most significant advantages of polyurethane foot technology is its ability to adapt to changes in residual limb volume throughout the day. Natural fluctuations in limb size due to fluid retention, activity level, and other factors can cause discomfort with rigid prosthetic interfaces. Polyurethane materials accommodate these changes by gently conforming to the limb's changing contours.

The temperature-responsive nature of polyurethane means the material becomes more pliable when warmed by body heat, creating a custom-fitted feel that improves throughout wear time. This adaptive characteristic reduces the need for frequent adjustments and enhances overall user satisfaction with the prosthetic device.

Clinical Applications and User Selection Criteria

Patient Assessment and Suitability

Clinical assessment for polyurethane foot prescription involves evaluating multiple factors including residual limb condition, activity level, and specific user needs. Prosthetists consider the patient's skin sensitivity, healing capacity, and previous experiences with prosthetic materials when determining suitability for polyurethane components.

Users with a history of skin complications, frequent prosthetic adjustments, or high activity levels often benefit most from polyurethane foot technology. The material's forgiving nature and superior comfort characteristics make it an excellent choice for challenging cases where traditional materials have proven inadequate.

Integration with Modern Prosthetic Systems

Contemporary prosthetic systems increasingly incorporate polyurethane foot components as part of comprehensive limb replacement solutions. The material's compatibility with various attachment mechanisms and suspension systems allows for seamless integration into existing prosthetic designs. This versatility ensures that users can benefit from polyurethane technology without requiring complete system replacement.

Advanced polyurethane foot designs often feature modular construction that allows for customization based on individual user requirements. This modularity enables prosthetists to fine-tune the prosthetic's performance characteristics while maintaining the protective benefits of polyurethane materials.

Maintenance and Care Considerations

Daily Cleaning and Hygiene Protocols

Proper maintenance of polyurethane foot components requires specific cleaning protocols to preserve the material's beneficial properties. Daily cleaning with mild, non-abrasive cleansers helps maintain the surface integrity while removing accumulated moisture and debris. Users should avoid harsh chemicals or abrasive materials that could compromise the polyurethane's smooth surface.

Regular inspection of the polyurethane foot surface allows for early detection of wear patterns or damage that could affect performance. Small tears or surface irregularities should be addressed promptly to prevent progression and maintain optimal skin protection. Professional evaluation and maintenance ensure continued performance and safety.

Long-term Performance Optimization

Maximizing the lifespan and performance of polyurethane foot components requires understanding the material's aging characteristics and replacement indicators. While polyurethane demonstrates excellent durability, factors such as user weight, activity level, and environmental exposure influence replacement timing.

Regular follow-up appointments with prosthetic professionals allow for performance monitoring and adjustment as needed. These sessions provide opportunities to assess skin condition, prosthetic fit, and overall user satisfaction while planning for future component replacement or upgrades.

FAQ

How long does a polyurethane foot typically last compared to other materials

A polyurethane foot generally lasts 18-24 months with regular use, which is significantly longer than traditional materials like foam or rubber that may require replacement every 6-12 months. The superior durability of polyurethane stems from its resistance to compression set and fatigue, making it a cost-effective choice despite higher initial investment costs.

Can people with diabetes safely use polyurethane foot prosthetics

Yes, individuals with diabetes often benefit greatly from polyurethane foot technology due to its superior pressure distribution and reduced friction characteristics. The material's ability to minimize hotspots and provide consistent cushioning helps protect vulnerable diabetic skin from ulceration and injury. However, users should maintain regular foot inspections and follow their healthcare provider's recommendations for diabetic foot care.

What makes polyurethane foot components better for sensitive skin

Polyurethane foot materials excel for sensitive skin because they provide consistent, even pressure distribution without creating friction points that can cause irritation. The material's smooth surface and conforming properties reduce shear forces while maintaining breathability to prevent moisture buildup. Additionally, medical-grade polyurethane is hypoallergenic and biocompatible, reducing the risk of allergic reactions.

How should I clean and maintain my polyurethane foot prosthetic

Clean your polyurethane foot daily with warm water and mild soap, avoiding harsh chemicals or abrasive materials that could damage the surface. Dry thoroughly and inspect for any signs of wear, tears, or surface irregularities. Store in a clean, dry environment and schedule regular check-ups with your prosthetist to ensure optimal performance and fit adjustments as needed.