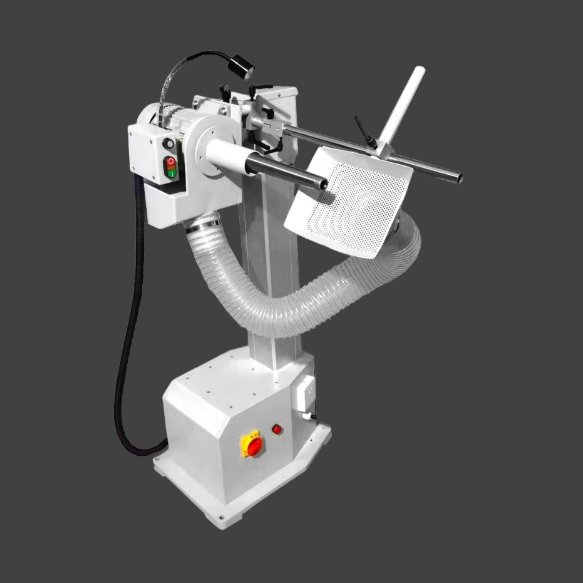

Advanced Customization and Comfort

The 3D printed limb excels in providing unparalleled customization options through its innovative design process. Each prosthetic is created using precise digital scans of the user's residual limb, ensuring an exact anatomical match that maximizes comfort and functionality. The technology allows for intricate adjustments to pressure points and weight distribution, significantly reducing the risk of skin irritation and discomfort. The design process incorporates user feedback and specific lifestyle requirements, resulting in a prosthetic that truly meets individual needs. The ability to fine-tune every aspect of the prosthetic, from the socket fit to the joint mechanisms, ensures optimal performance and user satisfaction.