Achieving optimal comfort in prosthetic devices represents one of the most critical aspects of successful limb replacement therapy. The journey toward comfortable prosthetic limb use involves multiple interconnected factors that directly influence a user's daily experience, mobility confidence, and overall quality of life. Understanding these determinants empowers both users and healthcare professionals to make informed decisions that maximize comfort while ensuring functional performance.

Modern prosthetic technology has evolved significantly, yet the fundamental challenge of achieving consistent comfort remains paramount. The complexity of human anatomy, combined with individual variations in lifestyle, activity level, and physical characteristics, creates unique comfort requirements for each prosthetic user. Research indicates that comfort-related issues account for approximately 60-70% of prosthetic abandonment cases, highlighting the critical importance of addressing comfort factors systematically.

The multifaceted nature of prosthetic comfort extends beyond simple physical fit considerations. Psychological comfort, thermal regulation, skin health maintenance, and long-term durability all contribute to the overall user experience. Healthcare professionals increasingly recognize that successful prosthetic outcomes depend heavily on comprehensive comfort optimization strategies that address both immediate and long-term user needs.

Interface Design and Material Selection

Socket Construction Principles

The prosthetic socket serves as the primary interface between the residual limb and the prosthetic device, making its design absolutely crucial for comfort optimization. Modern socket construction employs advanced materials and manufacturing techniques to create custom-fitted interfaces that distribute pressure evenly across the residual limb surface. Computer-aided design systems now enable prosthetists to create highly accurate socket geometries that account for individual anatomical variations and tissue characteristics.

Socket materials play a fundamental role in determining comfort levels throughout extended wear periods. Thermoplastic materials offer excellent durability and precise fitting capabilities, while carbon fiber composites provide superior strength-to-weight ratios for active users. The selection process considers factors such as residual limb volume fluctuations, activity requirements, and individual sensitivity levels to ensure optimal material compatibility.

Advanced socket designs incorporate pressure relief zones strategically positioned over sensitive anatomical structures such as bony prominences, nerve pathways, and areas prone to volume changes. These relief zones prevent concentrated pressure points that commonly cause discomfort, skin irritation, and reduced wearing tolerance. The integration of flexible materials in specific socket regions allows for natural tissue movement while maintaining secure attachment.

Liner Technology Integration

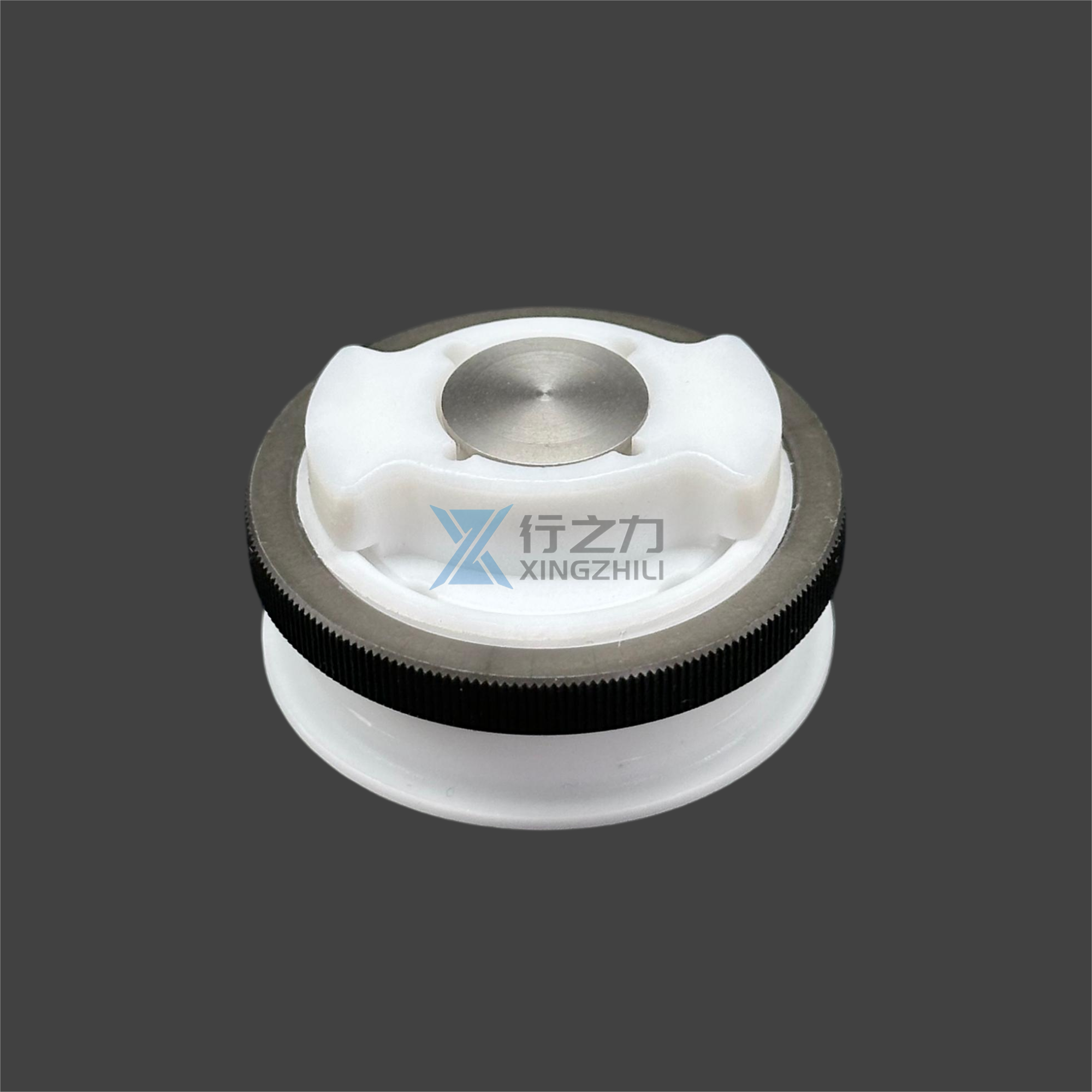

Prosthetic liners represent a critical component in achieving superior comfort levels by creating a protective barrier between the residual limb and the socket. Modern liner materials, including silicone, thermoplastic elastomers, and gel-based compounds, offer varying degrees of cushioning, adhesion, and moisture management properties. The selection of appropriate liner technology depends heavily on individual skin conditions, activity levels, and personal preferences.

Silicone liners have gained widespread acceptance due to their excellent biocompatibility, durability, and superior comfort characteristics. These liners conform closely to residual limb contours while providing consistent cushioning that reduces pressure concentrations and shear forces during ambulation. Advanced silicone formulations incorporate antimicrobial properties and enhanced breathability features that support long-term skin health maintenance.

The thickness profile of prosthetic liners significantly impacts comfort levels, with variations ranging from thin, flexible designs for maximum proprioception to thick, cushioned options for enhanced protection. Custom liner fabrication allows for precise thickness adjustments in specific anatomical regions, optimizing comfort while maintaining functional performance requirements.

Biomechanical Alignment and Suspension Systems

Optimal Component Alignment

Proper biomechanical alignment forms the foundation of comfortable prosthetic function by ensuring natural movement patterns and efficient load distribution throughout the prosthetic system. Misalignment issues commonly result in increased energy expenditure, compensatory movement patterns, and concentrated stress areas that significantly impact user comfort. Professional alignment procedures require extensive training and experience to achieve optimal outcomes that balance stability, function, and comfort requirements.

The alignment process considers multiple factors including residual limb characteristics, user activity goals, and individual gait patterns to establish optimal component positioning. Advanced alignment systems utilize adjustable components that allow for fine-tuning throughout the fitting process and accommodate changes in user needs over time. Dynamic alignment assessment using gait analysis technology provides objective data to guide alignment decisions and verify comfort optimization.

Proper alignment directly influences the distribution of forces acting on the residual limb during various activities. Well-aligned prosthetic systems minimize harmful stress concentrations while promoting natural movement mechanics that reduce fatigue and discomfort. The integration of shock-absorbing components and rotational adapters further enhances comfort by accommodating ground reaction forces and rotational movements that occur during normal ambulation.

Advanced Suspension Mechanisms

Suspension systems play a vital role in maintaining secure prosthetic attachment while minimizing discomfort associated with pistoning, rotation, and pressure fluctuations. Modern suspension technologies range from traditional suction systems to advanced locking mechanisms that provide reliable attachment without compromising comfort. The selection of appropriate suspension methods depends on residual limb characteristics, activity requirements, and individual dexterity levels.

Elevated vacuum suspension systems represent a significant advancement in prosthetic limb comfort technology by maintaining consistent negative pressure within the socket throughout the gait cycle. This technology reduces volume fluctuations, minimizes pistoning movements, and promotes improved proprioception that enhances user confidence and comfort levels. Advanced vacuum systems incorporate intelligent pressure monitoring and adjustment capabilities that automatically optimize suspension parameters based on activity demands.

Pin lock suspension systems offer reliable attachment through mechanical locking mechanisms while allowing for easy donning and doffing procedures. These systems distribute suspension forces across larger surface areas, reducing concentrated pressure points that commonly cause discomfort in traditional suspension methods. The integration of shuttle locks and similar mechanisms provides additional security while maintaining user-friendly operation characteristics.

Skin Health and Hygiene Management

Moisture Control Strategies

Effective moisture management represents a critical factor in maintaining long-term prosthetic limb comfort and preventing skin-related complications. The enclosed environment within prosthetic sockets creates conditions that promote moisture accumulation, bacterial growth, and skin irritation if not properly managed. Advanced moisture control strategies incorporate both material selection and design features that promote air circulation and moisture wicking capabilities.

Breathable socket materials and perforated designs allow for natural air exchange that reduces moisture buildup and promotes skin health maintenance. Modern liner materials incorporate moisture-wicking properties that transport perspiration away from skin surfaces while maintaining comfortable contact interfaces. The integration of ventilation systems and moisture evacuation channels further enhances comfort by preventing the accumulation of moisture that commonly leads to skin problems.

Antimicrobial treatments applied to socket surfaces and liner materials help prevent bacterial and fungal growth that can cause odor, skin irritation, and infection. These treatments maintain their effectiveness over extended periods, providing long-term protection that supports consistent comfort levels. Regular cleaning protocols and proper hygiene practices complement material-based moisture control strategies to ensure optimal skin health maintenance.

Pressure Distribution Optimization

Uneven pressure distribution represents one of the primary causes of prosthetic discomfort, skin breakdown, and reduced wearing tolerance. Advanced pressure mapping technologies enable prosthetists to identify and address problematic pressure concentrations during the fitting process. These diagnostic tools provide objective data that guides socket modifications and component adjustments to achieve optimal pressure distribution patterns.

Total surface bearing socket designs distribute loads across the entire residual limb surface, reducing peak pressures and promoting comfortable extended wear. This approach contrasts with traditional pressure-specific designs that concentrate loads on particular anatomical structures. The total surface bearing philosophy requires precise socket contouring and advanced materials that conform closely to residual limb anatomy while providing appropriate support characteristics.

Dynamic pressure relief systems incorporate adjustable elements that allow users to modify pressure distribution patterns based on activity requirements and comfort needs. These systems may include inflatable bladders, adjustable pads, or flexible inserts that provide customizable pressure relief in sensitive areas. The ability to make real-time adjustments enhances user autonomy and promotes consistent comfort throughout varying daily activities.

Individual Adaptation and Lifestyle Integration

Activity-Specific Comfort Considerations

Different activities place varying demands on prosthetic systems, requiring comfort optimization strategies that accommodate diverse functional requirements. Recreational activities, occupational tasks, and daily living activities each present unique challenges that influence prosthetic limb comfort and performance. Understanding these activity-specific requirements enables prosthetists to develop customized solutions that maintain comfort across multiple functional scenarios.

High-impact activities such as running, jumping, and sports participation require enhanced shock absorption and secure attachment mechanisms that prevent discomfort during dynamic movements. Specialized prosthetic components designed for athletic applications incorporate advanced materials and design features that maintain comfort while providing superior performance characteristics. The integration of energy storage and return technologies further enhances comfort by reducing the energy expenditure required for high-level activities.

Occupational requirements may necessitate extended standing periods, repetitive movements, or exposure to challenging environmental conditions that impact comfort levels. Prosthetic systems designed for occupational use incorporate features such as enhanced durability, superior moisture management, and specialized protection against workplace hazards. The consideration of workplace ergonomics and job-specific demands ensures that prosthetic solutions maintain comfort while supporting productive employment outcomes.

Long-Term Adaptation Strategies

Successful prosthetic limb comfort optimization requires ongoing attention to changing user needs, residual limb characteristics, and lifestyle requirements. Residual limb volume fluctuations, muscle strength changes, and evolving activity goals necessitate periodic adjustments and modifications to maintain optimal comfort levels. Comprehensive follow-up care programs ensure that prosthetic systems continue to meet user needs throughout extended periods of use.

Training programs that focus on proper donning and doffing techniques, skin care protocols, and equipment maintenance help users maximize comfort while preventing common problems. Educational initiatives that address realistic expectations, gradual adaptation strategies, and problem-solving techniques empower users to actively participate in their comfort optimization process. The development of strong communication channels between users and healthcare providers facilitates timely interventions when comfort issues arise.

Advanced prosthetic technologies continue to evolve, offering new opportunities for comfort enhancement through improved materials, design innovations, and manufacturing techniques. Staying current with technological developments enables prosthetists to incorporate the latest comfort-enhancing features into their practice. The integration of user feedback and outcome measurements guides the selection and implementation of new technologies that demonstrate proven comfort benefits.

FAQ

How long does it typically take to achieve comfortable prosthetic limb use?

The timeline for achieving comfortable prosthetic limb use varies significantly among individuals, typically ranging from several weeks to several months. Initial comfort adaptation often occurs within the first 2-4 weeks as users develop tolerance and proper wearing techniques. However, optimal comfort levels may require 3-6 months as residual limb tissue adapts, muscle strength improves, and prosthetic adjustments are refined. Factors such as residual limb condition, activity level, and individual adaptation capacity influence this timeline significantly.

What are the most common causes of prosthetic limb discomfort?

The primary causes of prosthetic limb discomfort include poor socket fit, inadequate pressure distribution, moisture accumulation, and biomechanical misalignment. Socket-related issues account for approximately 70% of comfort problems, including improper sizing, insufficient pressure relief, and inappropriate material selection. Skin-related complications such as irritation, breakdown, and infection frequently result from moisture management failures or excessive pressure concentrations in sensitive anatomical areas.

Can weather conditions affect prosthetic limb comfort levels?

Weather conditions significantly impact prosthetic limb comfort through temperature and humidity variations that affect residual limb volume, moisture accumulation, and material properties. Hot, humid conditions increase perspiration and moisture buildup within the socket, potentially causing skin irritation and reduced wearing tolerance. Cold temperatures may cause residual limb volume reduction, leading to loose socket fit and increased pistoning movements. Seasonal adjustments and climate-appropriate materials help maintain consistent comfort across varying weather conditions.

How often should prosthetic components be replaced to maintain optimal comfort?

Prosthetic component replacement schedules depend on usage patterns, material degradation, and changing user needs, with typical replacement intervals ranging from 6 months to 5 years for different components. Liners generally require replacement every 6-12 months due to material fatigue and hygiene considerations, while sockets may last 2-5 years with proper maintenance. Mechanical components such as joints and suspension systems typically require replacement every 3-5 years, depending on activity levels and wear patterns. Regular professional evaluations help determine optimal replacement timing to maintain comfort and function.