Assistive devices play a crucial role in enhancing the quality of life for individuals with disabilities, providing essential support for mobility, comfort, and independence. Among the many components that contribute to the effectiveness of these devices, stockinette stands out as a fundamental material that significantly impacts user comfort and device performance. This textile component serves as an interface between the user's skin and prosthetic or orthotic devices, creating a barrier that reduces friction, manages moisture, and improves overall wear comfort. Understanding the role of stockinette in assistive device manufacturing helps healthcare providers, prosthetists, and patients make informed decisions about device selection and customization.

The Fundamental Role of Stockinette in Assistive Device Design

Material Properties and Functionality

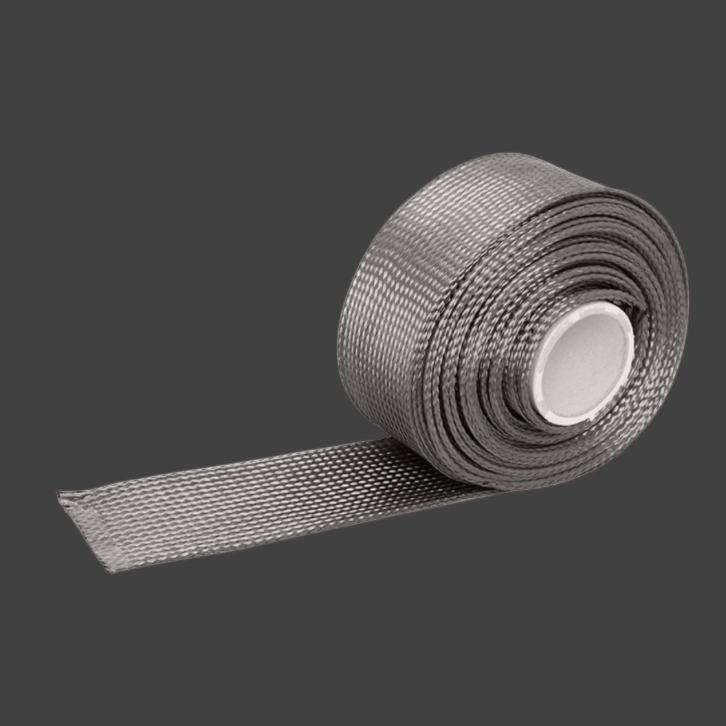

Stockinette material exhibits unique characteristics that make it indispensable in assistive device applications. The knitted construction of stockinette allows for excellent stretch and conformability, enabling it to accommodate various body contours and shapes without restricting movement. This flexibility is particularly important when working with prosthetic limbs or orthotic devices that must conform to irregular anatomical features. The material's breathability helps regulate temperature and moisture, preventing skin irritation and bacterial growth that can compromise device performance and user comfort.

The tensile strength of stockinette provides durability while maintaining softness against the skin. This balance ensures that the material can withstand the mechanical stresses associated with daily device use without compromising user comfort. Modern stockinette formulations often incorporate synthetic fibers that enhance moisture-wicking properties and antimicrobial characteristics, further improving the interface between user and device.

Application Methods in Device Manufacturing

In prosthetic and orthotic fabrication, stockinette application requires precise techniques to ensure optimal performance. The material is typically applied as the first layer over the residual limb or affected area, creating a smooth foundation for subsequent padding or device components. Proper sizing and tension during application prevent bunching or wrinkles that could create pressure points or compromise device fit.

Professional fabricators understand that stockinette must be carefully positioned to avoid seams or overlaps in high-pressure areas. The material's conformable nature allows it to be stretched and shaped during the molding process, ensuring intimate contact with the user's anatomy while maintaining uniform thickness throughout the application area.

Enhanced Comfort and User Experience Through Stockinette Integration

Skin Protection and Friction Reduction

One of the primary benefits of stockinette in assistive devices is its ability to protect the skin from direct contact with harder materials such as carbon fiber, fiberglass, or thermoplastic components. This protective barrier significantly reduces friction-related injuries, blistering, and skin breakdown that can occur with prolonged device use. The smooth surface of stockinette creates a sliding interface that allows natural movement without causing shear forces on the skin.

Users who wear assistive devices for extended periods particularly benefit from the cushioning effect that stockinette provides. The material distributes pressure more evenly across the contact surface, reducing hot spots and pressure concentrations that can lead to discomfort or tissue damage. This protective function is especially critical for individuals with compromised skin integrity or reduced sensation in the affected area.

Moisture Management and Hygiene Benefits

Effective moisture management is essential for maintaining skin health and device performance in assistive technology applications. Stockinette contributes to this goal through its moisture-wicking properties, which help transport perspiration away from the skin surface. This capability prevents the accumulation of moisture that can lead to bacterial growth, odor development, and skin maceration.

The breathable nature of stockinette allows air circulation within the device, promoting evaporation and maintaining a more comfortable microclimate for the user. Many modern stockinette formulations incorporate antimicrobial treatments that further enhance hygiene by inhibiting bacterial and fungal growth on the material surface.

Technical Specifications and Material Selection Criteria

Fiber Composition and Performance Characteristics

The selection of appropriate stockinette for assistive devices depends on understanding the various fiber compositions available and their respective performance characteristics. Natural fibers such as cotton provide excellent comfort and breathability but may lack the durability and moisture-wicking properties required for demanding applications. Synthetic fibers like polyester and nylon offer superior strength and moisture management but may compromise breathability and natural feel.

Blended stockinette materials combine the benefits of different fiber types to create optimal performance profiles for specific applications. These hybrid materials often incorporate specialty fibers such as bamboo or merino wool for enhanced comfort, or technical fibers with antimicrobial properties for improved hygiene. The knit structure itself plays a crucial role in determining stretch characteristics, recovery properties, and overall durability of the stockinette material.

Thickness and Density Considerations

Stockinette thickness and density significantly impact both comfort and device fit in assistive technology applications. Thicker stockinette provides more cushioning and protection but may affect the precision fit of custom-molded devices. Conversely, thinner materials offer better conformability and maintain tighter device tolerances but may provide less protection and comfort for sensitive users.

Professional device fabricators must carefully balance these considerations based on individual user needs, device type, and intended use patterns. The density of the knit structure affects both durability and stretch characteristics, with tighter knits providing longer wear life but potentially reduced comfort and conformability.

Quality Standards and Regulatory Compliance in Stockinette Manufacturing

Medical Device Regulations and Safety Requirements

Stockinette used in medical and assistive device applications must meet stringent quality standards and regulatory requirements to ensure user safety and device effectiveness. These materials are typically classified as medical devices or device components, subject to oversight by regulatory bodies such as the FDA in the United States or CE marking requirements in Europe.

Manufacturing facilities producing medical-grade stockinette must maintain quality management systems that comply with ISO 13485 standards, ensuring consistent product quality and traceability throughout the production process. Regular testing protocols verify material properties such as tensile strength, elongation, moisture management, and biocompatibility to ensure compliance with established specifications.

Testing Protocols and Quality Assurance

Comprehensive testing protocols evaluate stockinette performance across multiple parameters relevant to assistive device applications. These tests include mechanical property assessments, moisture management evaluation, skin compatibility studies, and durability testing under simulated use conditions. Bacterial resistance testing and antimicrobial efficacy studies are particularly important for materials intended for extended skin contact.

Quality assurance programs typically include batch testing, statistical process control, and ongoing monitoring of manufacturing parameters to maintain consistent product quality. Traceability systems ensure that any quality issues can be quickly identified and addressed, protecting end users and maintaining confidence in the material's performance characteristics.

Innovation and Future Developments in Stockinette Technology

Advanced Material Technologies

The future of stockinette technology in assistive devices lies in the development of advanced materials that offer enhanced performance characteristics. Smart textiles incorporating conductive fibers may enable integration of sensors for monitoring device fit, user activity, or physiological parameters. These innovations could provide valuable feedback to healthcare providers and users about device performance and usage patterns.

Nanotechnology applications in stockinette manufacturing offer possibilities for creating materials with self-cleaning properties, enhanced antimicrobial effects, or improved moisture management capabilities. Phase-change materials integrated into stockinette fibers could provide temperature regulation, maintaining optimal comfort levels across varying environmental conditions.

Customization and Personalization Approaches

Emerging manufacturing technologies enable greater customization of stockinette properties to meet individual user needs. 3D knitting technologies allow for variable thickness, density, and fiber composition within a single stockinette piece, optimizing performance for specific anatomical regions or pressure distribution requirements.

Digital manufacturing approaches may eventually enable on-demand production of stockinette with properties tailored to individual users based on their specific requirements, activity levels, and skin sensitivity. This level of personalization could significantly improve user outcomes and device acceptance rates.

FAQ

What makes stockinette different from regular fabric in assistive devices

Stockinette differs from regular fabric through its specialized knit construction that provides four-way stretch, excellent conformability, and moisture-wicking properties specifically designed for skin contact applications. Unlike woven fabrics, stockinette maintains consistent stretch and recovery properties that allow it to conform to irregular shapes without creating pressure points or restricting movement, making it ideal for prosthetic and orthotic applications.

How often should stockinette be replaced in assistive devices

The replacement frequency for stockinette depends on usage patterns, material quality, and individual user factors, but typically ranges from daily for high-use applications to weekly for moderate use. Users should monitor the material for signs of wear, loss of elasticity, odor retention, or visible deterioration. Regular replacement ensures optimal hygiene, comfort, and device performance while preventing potential skin irritation or infections.

Can stockinette be used with all types of assistive devices

While stockinette is compatible with most prosthetic and orthotic devices, specific applications may require different material grades or thicknesses based on device type, user needs, and contact pressure requirements. Upper extremity prosthetics may use thinner stockinette for better dexterity, while lower extremity devices might require thicker, more durable materials. Healthcare providers should evaluate individual requirements to determine the most appropriate stockinette specification.

What are the signs that stockinette quality may be compromising device performance

Signs of compromised stockinette include loss of elasticity leading to bunching or wrinkles, visible wear or thin spots, persistent odors despite cleaning, skin irritation or breakdown, and reduced moisture-wicking effectiveness. These indicators suggest that the material is no longer providing adequate protection and comfort, potentially affecting device fit and user satisfaction. Prompt replacement helps maintain optimal device performance and user outcomes.

Table of Contents

- The Fundamental Role of Stockinette in Assistive Device Design

- Enhanced Comfort and User Experience Through Stockinette Integration

- Technical Specifications and Material Selection Criteria

- Quality Standards and Regulatory Compliance in Stockinette Manufacturing

- Innovation and Future Developments in Stockinette Technology

- FAQ