Superior Vacuum Integrity and Sealing Technology

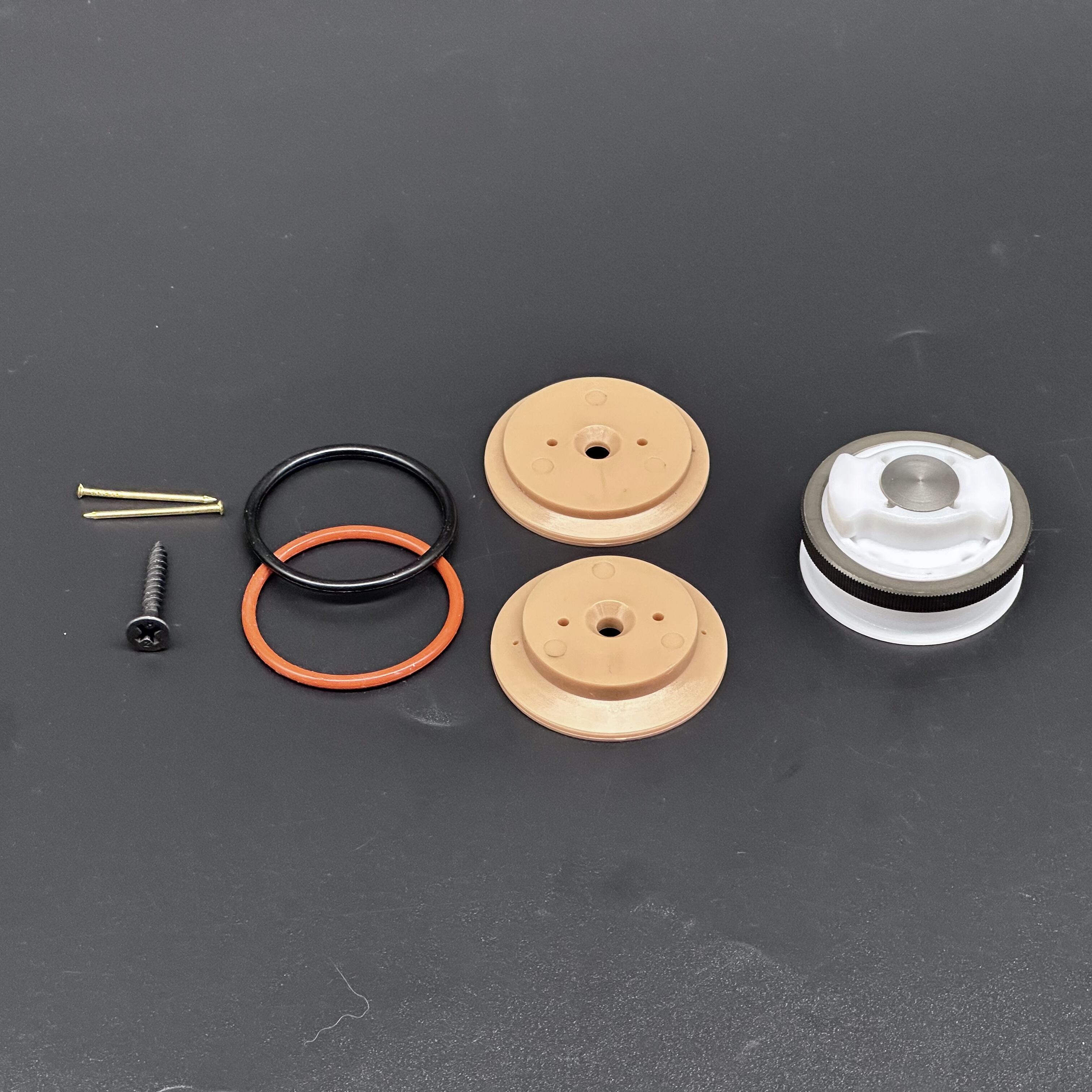

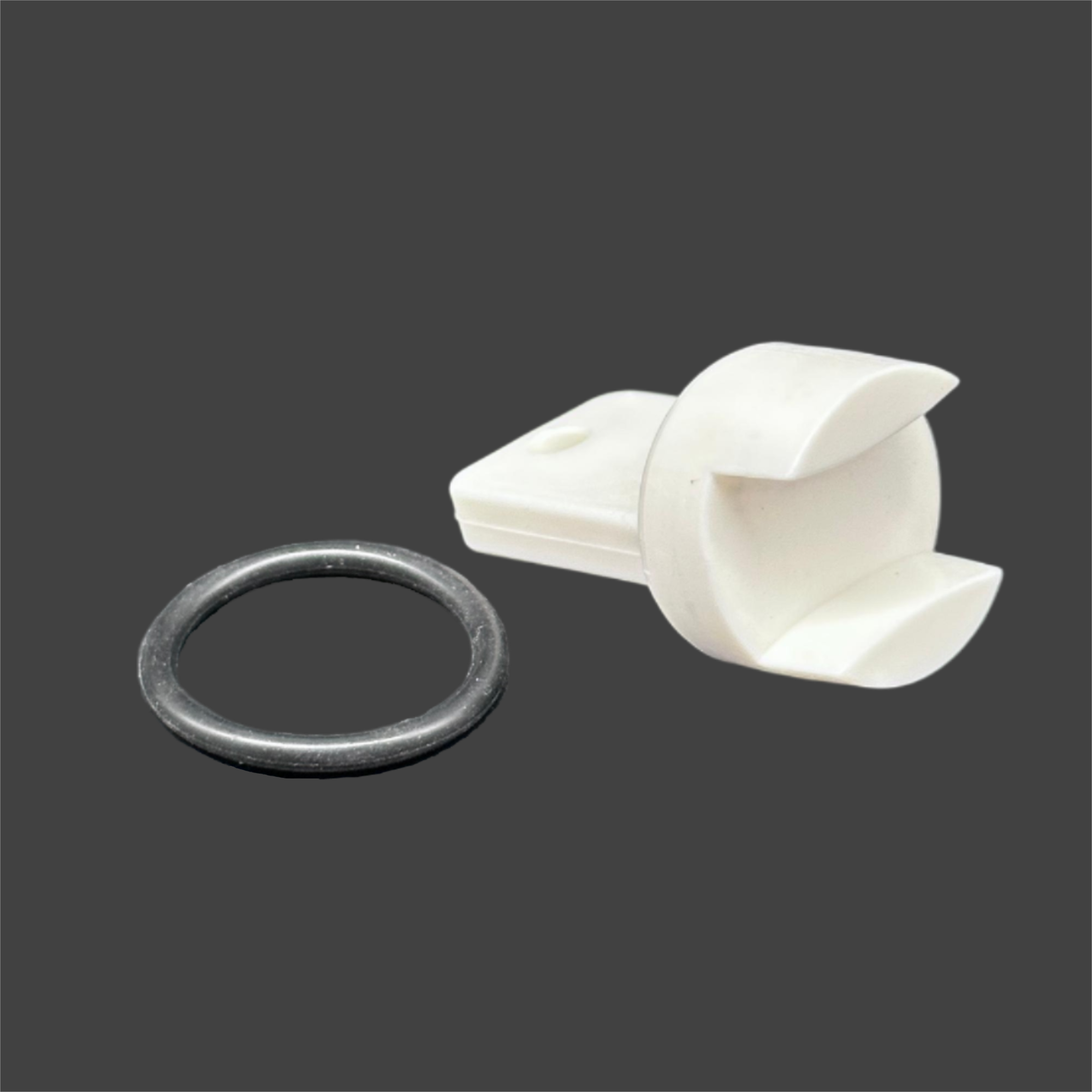

The precision vacuum valve's outstanding vacuum integrity stems from its advanced sealing technology, incorporating specialized materials and innovative design features. The valve utilizes high-performance sealing elements, often combining metal-to-metal seals with specialized elastomer components, ensuring minimal leakage rates even under challenging conditions. This sealing system maintains its effectiveness across a wide temperature range and remains stable during long-term operation. The design includes precision-machined mating surfaces that create an exceptional seal when closed, preventing unwanted gas infiltration and maintaining system purity. The sealing mechanism's durability ensures consistent performance over thousands of cycles, reducing maintenance requirements and extending operational life. This reliable sealing technology is particularly crucial in applications requiring ultra-high vacuum conditions or handling sensitive materials.