Transforming Lives Through Advanced Prosthetic Solutions

The evolution of disability prosthesis technology has revolutionized the way individuals with limb differences navigate their daily lives. Modern prosthetic devices offer unprecedented levels of comfort, functionality, and natural movement that were unimaginable just decades ago. As we explore the transformative impact of these innovative solutions, we'll discover how they're not just replacing limbs, but enhancing lives through improved biomechanics and reduced physical strain.

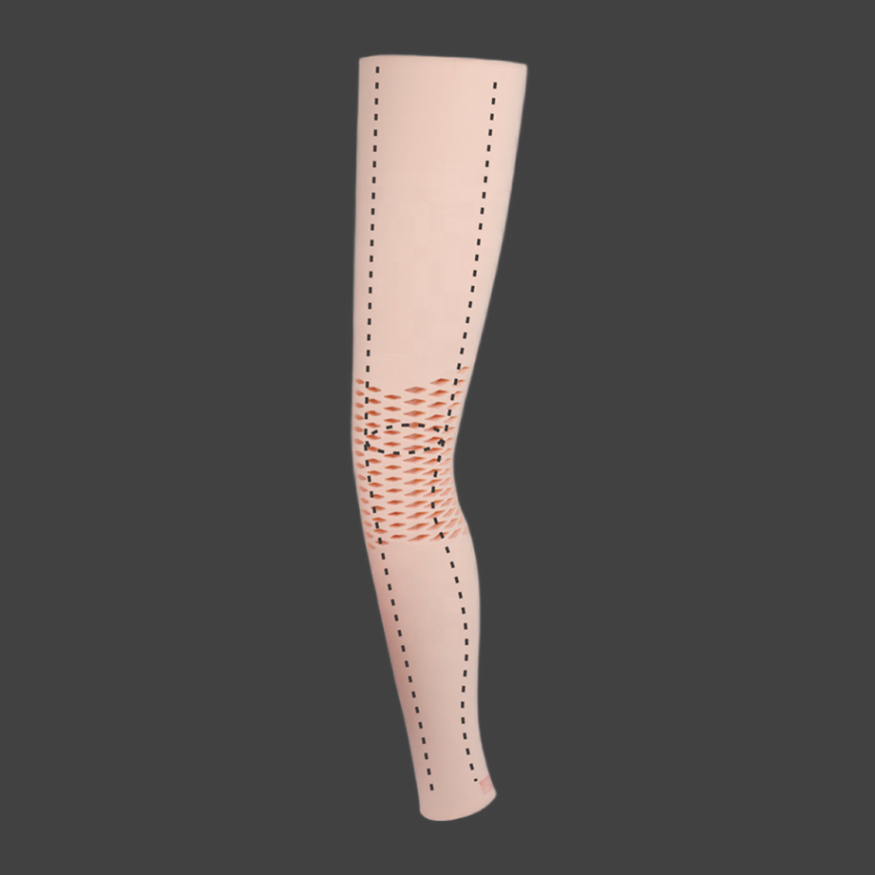

Today's disability prosthesis options incorporate cutting-edge materials, sophisticated socket designs, and advanced adaptation mechanisms that work in harmony with the human body. These developments have led to remarkable improvements in user comfort and significant reductions in the physical demands placed on both the residual limb and the entire musculoskeletal system.

Advanced Materials and Design Innovation

Lightweight Components for Enhanced Mobility

Modern disability prosthesis design prioritizes the use of lightweight materials such as carbon fiber, titanium alloys, and advanced polymers. These materials significantly reduce the overall weight of the prosthetic device while maintaining exceptional durability and strength. The reduced mass means less energy expenditure during movement, allowing users to maintain activity for longer periods without experiencing excessive fatigue.

The strategic use of these materials also enables better weight distribution and balance, crucial factors in preventing overcompensation and related strain injuries. For instance, carbon fiber components can be engineered to flex and respond to movement patterns, providing natural energy return during walking and other activities.

Customized Socket Technology

The socket interface between the residual limb and disability prosthesis represents perhaps the most critical component for ensuring user comfort. Modern socket designs utilize computer-aided design and manufacturing (CAD/CAM) technology to create precise, individualized fits. These custom solutions account for unique anatomical features, pressure points, and movement patterns specific to each user.

Advanced socket systems also incorporate adaptive materials that respond to volume changes in the residual limb throughout the day. This dynamic adjustment capability helps maintain consistent comfort and secure fit, reducing the risk of skin irritation and improving overall prosthesis performance.

Biomechanical Optimization and Support

Dynamic Alignment Systems

A properly aligned disability prosthesis is essential for minimizing physical strain and optimizing gait efficiency. Modern prosthetic solutions feature dynamic alignment systems that can be fine-tuned to match an individual's natural movement patterns. These adjustments help distribute forces evenly across the residual limb and adjacent joints, reducing the risk of developing secondary conditions.

The implementation of microprocessor-controlled joints and adaptive alignment mechanisms allows the prosthesis to respond to changes in terrain, speed, and activity level. This responsive technology helps maintain optimal biomechanical alignment throughout various daily activities, from walking to climbing stairs.

Energy Storage and Return

Contemporary disability prosthesis designs incorporate energy storage and return mechanisms that help reduce the metabolic cost of movement. These systems capture and store energy during the stance phase of gait, then release it at the appropriate moment to assist with forward propulsion. This feature is particularly beneficial for reducing fatigue during extended periods of activity.

Advanced foot and ankle components utilize specialized spring elements and carbon fiber layouts to mimic the natural elastic response of biological tissues. This biomimetic approach helps users maintain a more efficient and natural gait pattern while requiring less physical effort.

Comfort Enhancement Technologies

Temperature and Moisture Management

Managing heat and moisture at the interface between the residual limb and disability prosthesis is crucial for long-term comfort. Modern liner materials incorporate advanced moisture-wicking properties and temperature-regulating features that help maintain an optimal environment for the residual limb. These technologies work to prevent excessive sweating and the associated problems of skin maceration and bacterial growth.

Some prosthetic systems now include active ventilation systems or phase-change materials that can help regulate temperature more effectively. These innovations significantly improve wear time comfort and reduce the risk of skin-related complications.

Smart Cushioning Systems

The integration of smart cushioning systems in disability prosthesis design helps protect sensitive tissues from impact forces and pressure points. These systems may include gel layers, foam materials with varying densities, or even electronic cushioning elements that can adjust their properties based on user activity levels.

Advanced cushioning technologies work in conjunction with the socket design to distribute pressure evenly across the residual limb, reducing the risk of tissue damage and improving overall comfort during extended use.

Frequently Asked Questions

How often should a disability prosthesis be adjusted or replaced?

A disability prosthesis typically requires regular adjustments every 3-6 months to maintain optimal fit and function. Complete replacement is usually recommended every 3-5 years, though this can vary based on usage patterns, growth changes, and wear and tear. Regular consultations with a prosthetist help ensure the device continues to provide maximum comfort and minimal strain.

What are the signs that a prosthesis needs adjustment?

Key indicators include increased discomfort, skin irritation, changes in fit (either loose or tight), unusual sounds from the device, decreased performance, or changes in gait pattern. Any persistent pain or discomfort should be addressed promptly to prevent potential complications or strain injuries.

Can I exercise or play sports with a disability prosthesis?

Modern prosthetic devices are designed to accommodate various levels of physical activity, including sports and exercise. However, it's important to work with your prosthetist to ensure your device is appropriate for your intended activities. Many users benefit from having specialized components or entire prostheses designed specifically for athletic activities.