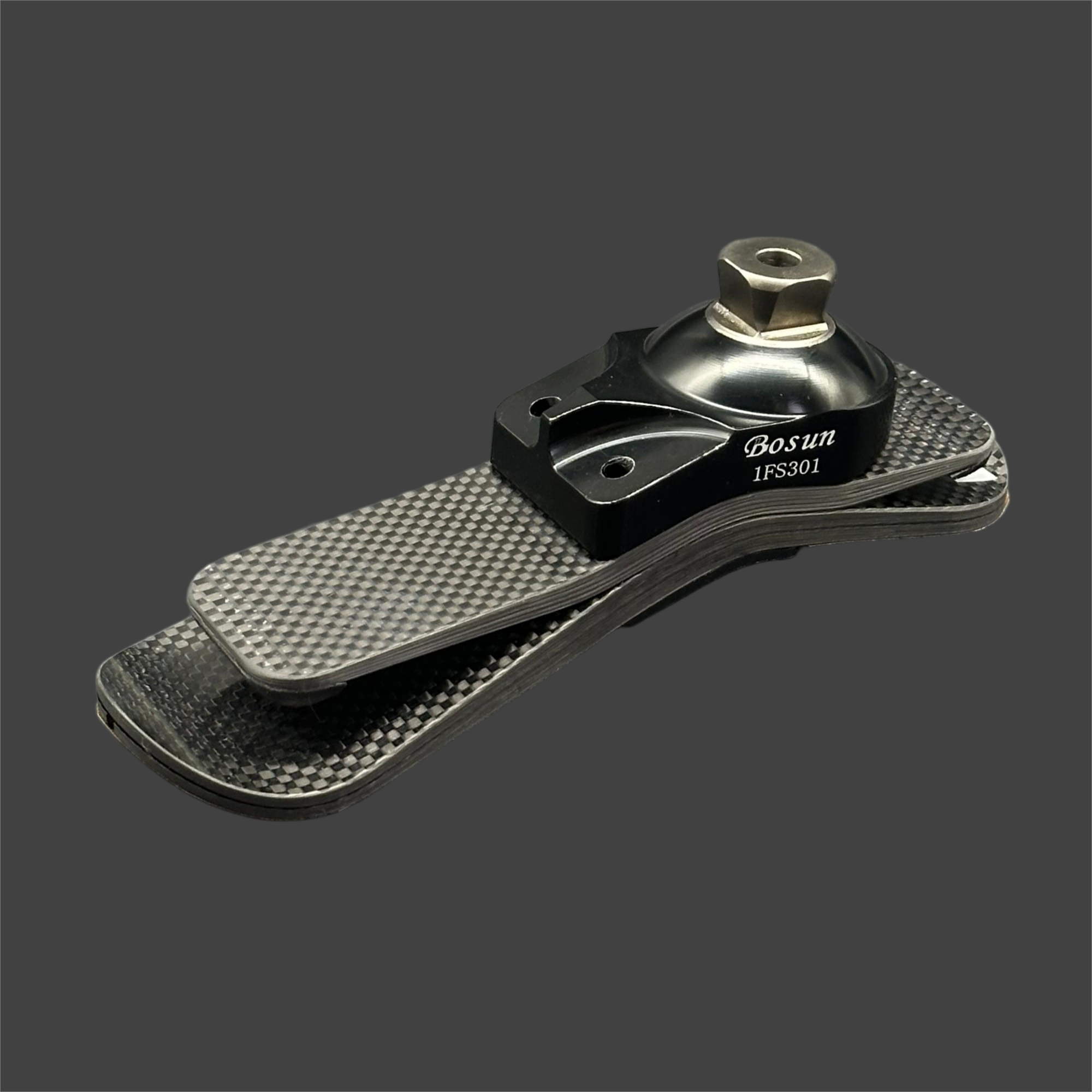

Superior Surface Control and Finishing

The prosthetic sanding drum's engineered design delivers exceptional control over surface finishing operations. Its precision-manufactured cylindrical form ensures consistent contact pressure across the entire working area, eliminating uneven wear patterns and hotspots. The drum's balanced construction minimizes vibration during operation, allowing practitioners to achieve precise material removal with minimal effort. Multiple grit options enable progressive refinement of surfaces, from initial shaping to final polishing, while maintaining geometric accuracy. The drum's ability to conform to complex contours ensures uniform finishing on curved surfaces, critical for optimal prosthetic fit and patient comfort. Advanced abrasive materials used in modern drums provide extended service life and consistent performance throughout their operational lifespan.