Advanced Material Engineering and Customization

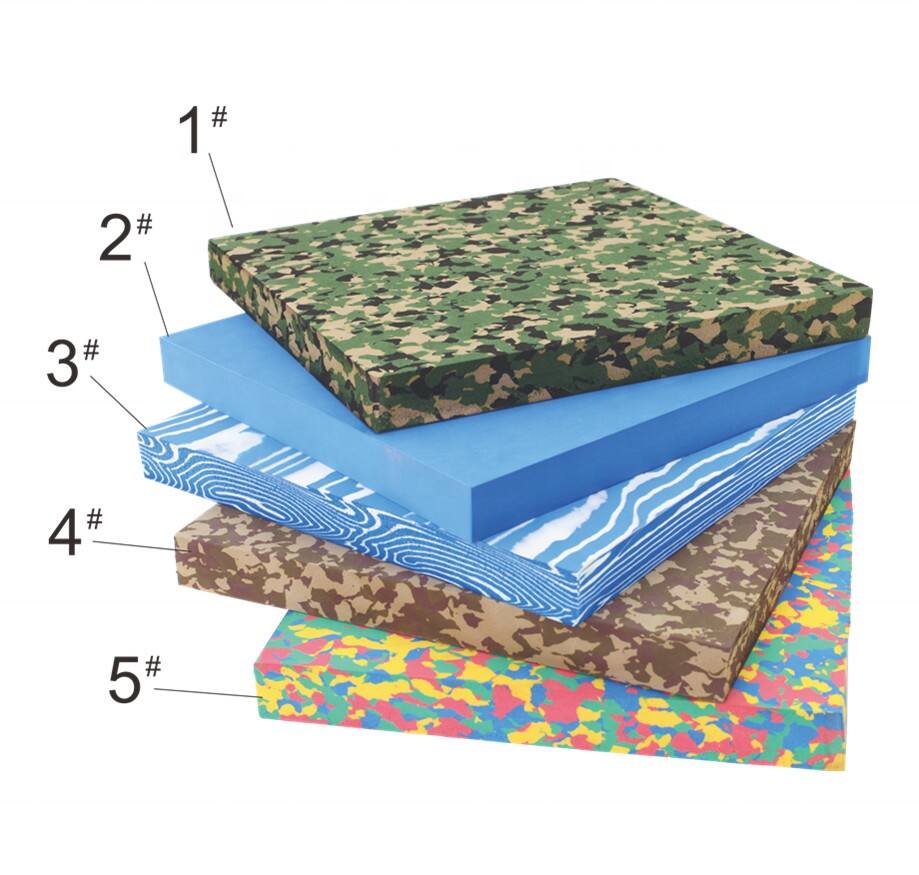

The engineering behind resilient prosthetic polyurethane showcases remarkable advances in material science, offering unprecedented levels of customization and performance. The material's molecular structure can be precisely engineered to achieve specific mechanical properties, allowing manufacturers to create prosthetic components that perfectly match individual patient requirements. This customization extends to adjusting hardness levels, elasticity, and compression set properties, ensuring optimal comfort and functionality. The material's advanced polymer chemistry enables the integration of various additives and modifiers to enhance specific properties such as UV resistance, antimicrobial protection, and color stability. This level of customization makes it possible to address unique patient needs while maintaining the material's core benefits.