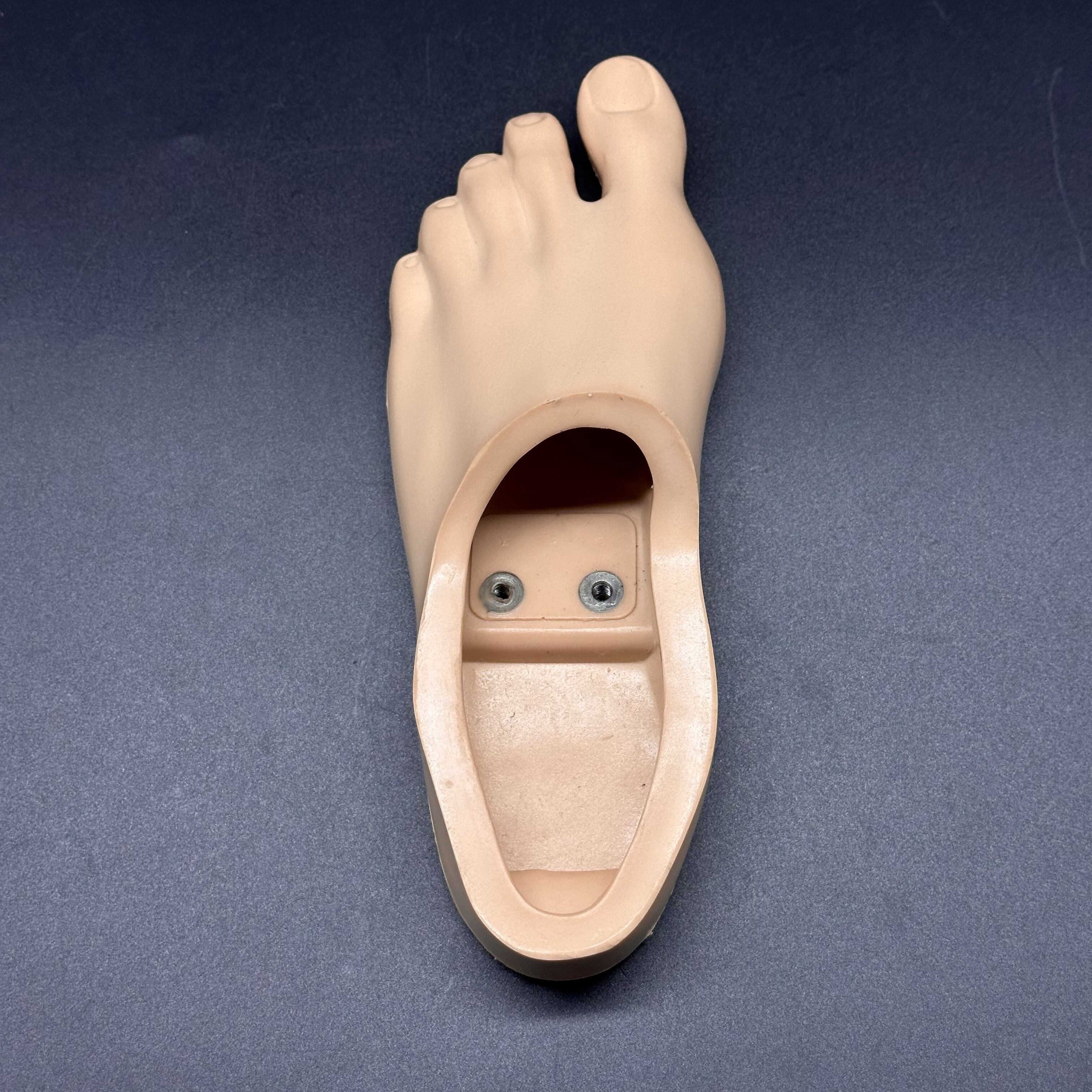

탁월한 커스터마이징 기능

맞춤 제작된 폴리우레탄은 무궁무진한 커스터마이징 가능성으로 주목받고 있으며, 제조업체가 특정 응용 분야의 요구 사항에 정확하게 부합하는 부품을 제작할 수 있게 해줍니다. 이 소재는 Shore 경도 값이 20A에서 80D까지 다양하게 조성되어 매우 부드럽고 유연한 상태에서부터 단단하고 강성 있는 상태까지 폭넓은 물성 구현이 가능합니다. 이러한 다용도성은 엔지니어들이 고부하 지지력, 우수한 내마모성 또는 특정 화학 저항성 등과 같은 요구 조건에 따라 부품을 최적화할 수 있게 해줍니다. 커스터마이징 과정은 물리적 특성에만 국한되지 않으며, 색상 매칭, 표면 질감 변경, 난연성 또는 정전기 방출과 같은 향상된 성능 특성을 위한 특수 첨가제의 적용도 포함됩니다. 이러한 수준의 맞춤화를 통해 각 부품이 본래의 기능에 정확하게 부합하도록 보장할 뿐만 아니라 여러 개의 부품을 하나의 보다 효율적인 설계로 통합할 수도 있습니다.