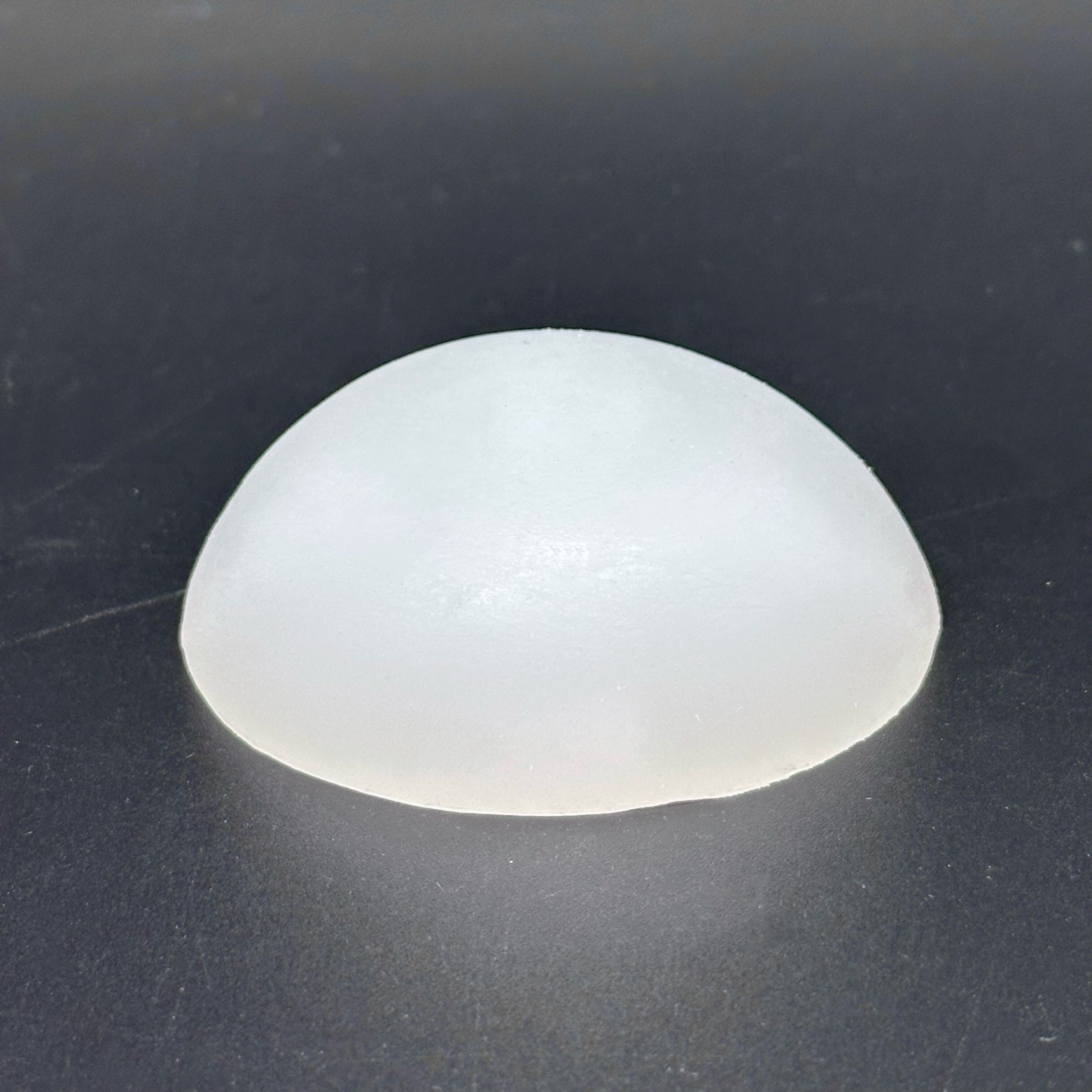

অতুলনীয় স্থিতিস্থাপক পুনরুদ্ধার এবং দীর্ঘস্থায়ীতা

অতিপ্রত্যাস্থ সিলিকনের চরম প্রত্যাস্থ পুনরুদ্ধারের ক্ষমতাই এর চিহ্নিতকারী বৈশিষ্ট্য, যা উপকরণের কার্যকারিতার ক্ষেত্রে নতুন মান নির্ধারণ করে। এই বিপ্লবী উপকরণটি নিজের আসল দৈর্ঘ্যের 1000% পর্যন্ত প্রসারিত হতে পারে যখন এর পূর্ণ কাঠামোগত অখণ্ডতা বজায় রেখে নিরবচ্ছিন্ন বিকৃতি ছাড়াই এটি নিজের আদি মাত্রায় ফিরে আসে। এই অসাধারণ বৈশিষ্ট্যটি এর অনন্য আণবিক স্থাপত্য থেকে উদ্ভূত হয়, যেখানে অপটিমাইজড ক্রস-লিঙ্কিং ঘনত্ব এবং সাবধানে প্রকৌশলীকৃত পলিমার শৃঙ্খল দৈর্ঘ্য রয়েছে। অসংখ্য বিকৃতি চক্রের মধ্য দিয়ে এই বৈশিষ্ট্যগুলি বজায় রাখার ক্ষমতা থাকার কারণে উপকরণটির টেকসই প্রকৃতি প্রমাণিত হয়, যা পুনরাবৃত্ত চাপের অধীনে স্থায়ী কার্যকারিতা প্রয়োজনীয় অ্যাপ্লিকেশনগুলির জন্য এটিকে আদর্শ করে তোলে। চরম প্রত্যাস্থতা এবং টেকসইযোগ্যতার এই সংমিশ্রণটি দীর্ঘতর পণ্য আয়ু, কম রক্ষণাবেক্ষণের প্রয়োজনীয়তা এবং গুরুত্বপূর্ণ অ্যাপ্লিকেশনগুলিতে উন্নত নির্ভরযোগ্যতা অর্থে পরিণত হয়। ক্লান্তির প্রতি উপকরণটির প্রতিরোধ ক্ষমতা কঠোর পরিবেশেও স্থিতিশীল কার্যকারিতা নিশ্চিত করে, ব্যবহারকারীদের তাদের পণ্যের দীর্ঘমেয়াদী কার্যকারিতায় আস্থা প্রদান করে।